Injection molding services

Excellence in plastic part production

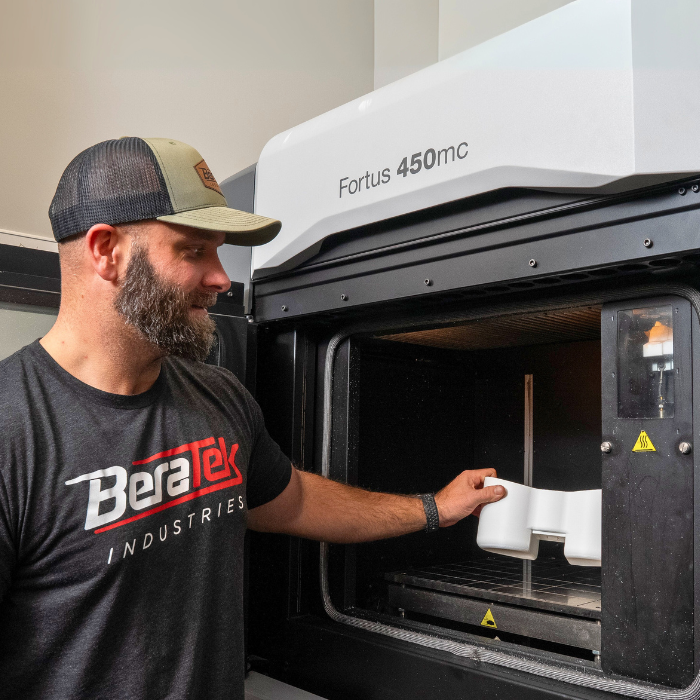

Injection molding is one of the most reliable ways to produce durable, repeatable plastic parts at scale. At BeraTek, we help businesses turn ideas into production-ready components with end-to-end injection molding services. Whether you need a prototype, a short run, or high-volume manufacturing, our team guides you through each step.

Types of Injection Molding

At BeraTek, our injection molding services are built to support you from idea to finished part. Whether you already have a finalized design or you’re still shaping your concept, we handle the engineering, tooling, and production work that brings your product to life. Below is a quick look at what we offer and how we help you move from prototype to full-scale manufacturing.

Custom Injection Molding

We design and mold parts tailored to your product. Our team handles material selection, tooling, manufacturing, and quality control so you get parts that match your specifications.

Insert and Overmolding

If your part requires threaded inserts, fasteners, or bonding rubber-like materials to rigid plastics, we can combine components during the molding process to improve strength and performance.

Low-Volume and High-Volume Production

We support early product development as well as long production runs. This gives you flexibility to scale without switching manufacturers.

Tooling Design and Mold Management

Our engineers design efficient tools to keep your part quality high and your per-piece cost low. We also maintain and store your molds for the life of your project.

Why Use Injection Molding?

Injection molding uses a wide variety of materials, each chosen for its unique properties to meet specific product requirements. Material selection is critical, as each choice affects the end product’s performance, appearance, and suitability for the intended use.

- Consistent part quality

- Cost-effective at scale

- Wide material variety

- Complex shapes and features

- Fast production once tooling is created

Injection Molding Materials

Injection molding uses a wide variety of materials, each chosen for its unique properties to meet specific product requirements. Material selection is critical, as each choice affects the end product’s performance, appearance, and suitability for the intended use.

Industries We Serve

See how major industries use plastic injection molding to produce repeatable products of any size, shape, or thermoplastic material.

Maximizing Production Efficiency In Injection Molding

With the agility to shift seamlessly between short-run and high-volume production, we bridge quality-driven production excellence to end-user satisfaction, positioning your product to make waves in the market.

We’re not just manufacturers, we’re engineers driven by a passion for creating quality products that exceed expectations. With the capacity to consistently produce high volumes of parts while maintaining strict quality standards, we apply lean manufacturing principles to optimize efficiency, reduce waste, and ensure rapid scalability.

Process

Concept to Completion

Step 1

Initial Consultation & Project Specifications

We begin by discussing project needs, specifications, and goals to establish a clear and shared vision.

Step 2

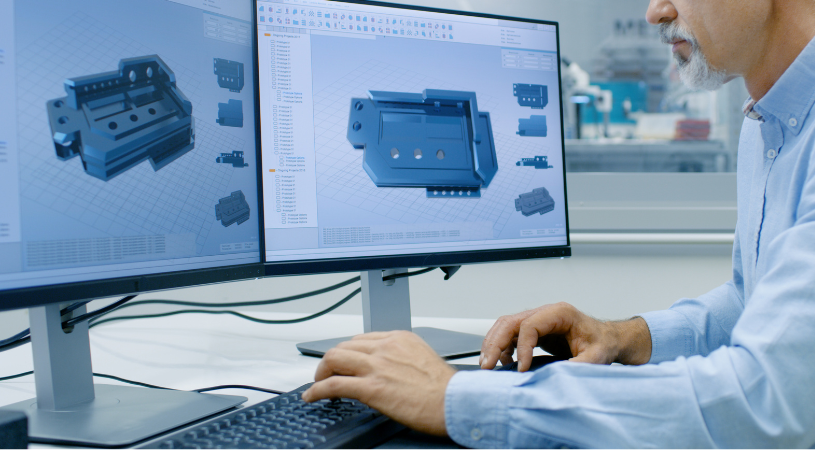

DFM and Mold Design

We review and refine your part model to ensure it’s optimized for manufacturing at scale.

Step 3

Production and Quality Assurance

We produce parts efficiently and consistently, with rigorous quality checks to meet exacting standards.

Production and Injection Molding FAQs

What exactly does BeraTek offer in its injection molding service?

At BeraTek, we provide full-service plastic injection molding — from material selection and mold setup to part production, finishing, and quality assurance. Our vertically integrated workflow means we can take your project from design or prototype straight into production, all under one roof.

What kinds of plastics and materials can you mold?

We work with a broad range of thermoplastic resins and engineering-grade plastics. This includes commodity materials like polypropylene (PP) and polyethylene (PE), as well as higher-performance engineering resins like ABS, polycarbonate (PC), nylon (PA), and specialty blends. We help select the right material based on your application needs for strength, flexibility, durability, finish, and cost.

What injection molding machine sizes or tonnages does BeraTek operate?

Our mold shop is equipped with injection presses ranging from small to moderate tonnages. This lets us handle small intricate parts as well as mid-size components. When we scale production, our in-house tooling and prototyping teams make sure the mold, the machine, and the part design are all aligned for smooth production and consistent quality.

How does BeraTek address part quality and consistency?

We follow rigorous quality control and process management practices, including:

-

Precision mold setup and calibration

-

Process validation runs to dial in temperature, pressure, and cooling

-

In-process monitoring of cycle times and part dimensions

-

Post-molding inspection, finishing, and defect-removal (such as de-flash, trimming, or secondary machining)

-

Regular mold maintenance to ensure consistent output over time

Can you handle low-volume or high-volume production runs?

Yes. One of our strengths is flexibility. We can support low-volume production (prototype or pilot runs) and scale up to moderate-volume production runs as demand grows. Because of our in-house tooling and prototyping, we can efficiently ramp up production while maintaining part quality and controlling costs.

How does BeraTek help reduce production risk and cost?

We reduce risk through:

-

Early prototyping and validation, which helps uncover design flaws before full-scale tooling

-

Design for Manufacturability (DFM) to optimize wall thickness, draft, gating, and cooling early in the process

-

Close integration between design, tooling, and molding teams, so we avoid “handoff surprises”

-

Ongoing mold maintenance and process tuning to minimize downtime and scrap

These practices help shorten production cycles, reduce scrap, and improve first-pass yield — which all translate to lower costs and faster time-to-market.

What turnaround times can I expect for injection-molded parts?

Turnaround depends on part complexity, mold readiness, production volume, and finishing requirements. For pre-validated tooling and simple geometries, the cycle from order to parts can be a matter of days or a few weeks. For new tooling or higher complexity components, the timeline may extend to several weeks or longer. We work closely with you to provide realistic schedules and keep the project on track.

How does BeraTek manage secondary operations and finishing?

We offer a variety of post-molding services, including trimming, de-flash, surface finishing, secondary machining, assembly, and inspection. Wherever feasible, we perform these steps in-house or through trusted partners to help minimize logistics delays and ensure consistent final quality.

Why should I choose BeraTek for my injection molding project?

You’ll benefit from:

-

A fully integrated service chain (design → prototyping → tooling → molding → finishing)

-

Close collaboration between engineering and production teams, reducing surprises and improving lead times

-

Flexible scalability — from low-volume prototypes to production volumes

-

Commitment to quality, process control, and continuous improvement

-

Transparent communication and a hands-on, problem-solving approach to getting your parts made right