Commercial Sanitation Injection Molding

Plastic components that uphold the highest standards of hygiene and safety.

By collaborating closely with our clients, we create innovative solutions that enhance both cleanliness and operational efficiency.

Innovation

Elevating Commercial Sanitation Brands with Advanced Manufacturing

Leading commercial sanitation suppliers partner with experienced injection molders to achieve greater design versatility, production efficiency, and faster product launches.

Dedication

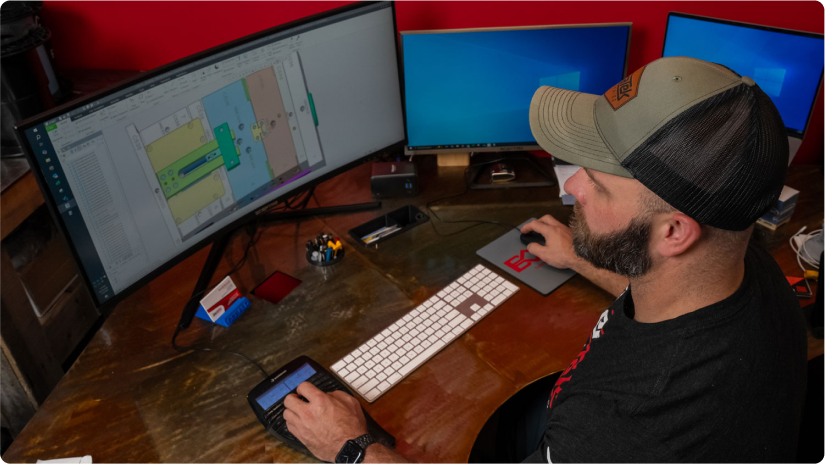

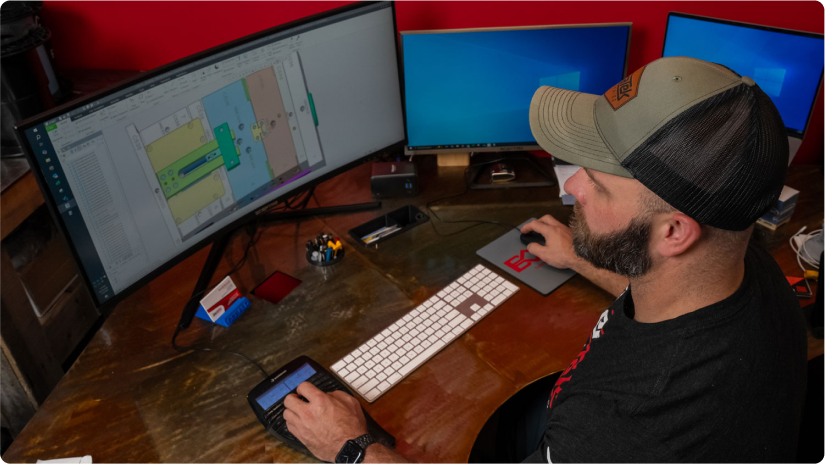

Our advanced CAD software and simulations help us identify and address design challenges, enable efficient revisions, and minimize prototyping delays.

Excellence

Smooth Integration from Design to Full-Scale Production

With competition intensifying in the commercial sanitation industry, fast turnaround and efficiency are key. BeraTek Industries excels at delivering high-quality products with rapid production cycles.

Production & Injection MoldingAbout Us

Why Commerical Sanitation Companies Choose BeraTek

The journey from initial design to full-scale production is a critical phase where efficiency can significantly impact overall project timelines. We employ advanced design and engineering tools that facilitate seamless transitions between stages.

-

Advanced Tooling & Precision Engineering

-

Material Expertise and Customization

-

Scalability and Production Efficiency

-

End-to-End Solutions and Support

Advanced Tooling & Precision Engineering

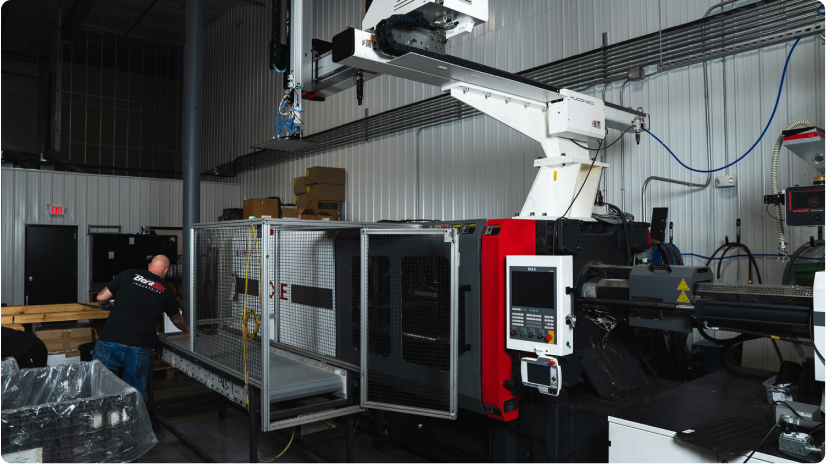

We utilize high-precision tooling, cutting-edge CAD software, and implement systems to ensure accuracy, consistency, and faster production cycles.

Learn More

Material Expertise and Customization

Offering a wide range of resins, additives, and composite materials tailored to specific industry requirements, such as high-heat resistance, durability, or eco-friendly options.

Learn More

Scalability and Production Efficiency

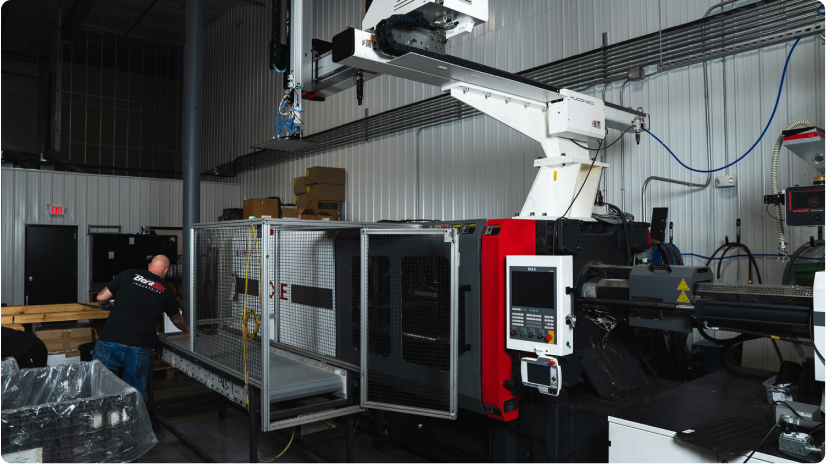

The ability to scale from prototyping to full-scale production seamlessly while leveraging multi-cavity molds, lean manufacturing, and automation to optimize cost and lead times.

Learn More

End-to-End Solutions and Support

Providing comprehensive services from design for manufacturability (DFM) and prototyping to post-production finishing, assembly, and supply chain management to ensure a seamless customer experience.

Learn More

Advanced Tooling & Precision Engineering

We utilize high-precision tooling, cutting-edge CAD software, and implement systems to ensure accuracy, consistency, and faster production cycles.

Learn More

Material Expertise and Customization

Offering a wide range of resins, additives, and composite materials tailored to specific industry requirements, such as high-heat resistance, durability, or eco-friendly options.

Learn More

Scalability and Production Efficiency

The ability to scale from prototyping to full-scale production seamlessly while leveraging multi-cavity molds, lean manufacturing, and automation to optimize cost and lead times.

Learn More

End-to-End Solutions and Support

Providing comprehensive services from design for manufacturability (DFM) and prototyping to post-production finishing, assembly, and supply chain management to ensure a seamless customer experience.

Learn More

Commercial Sanitation Plastic Product Materials

Injection molding uses a wide variety of materials, each chosen for its unique properties to meet specific product requirements. Material selection is critical, as each choice affects the end product’s performance, appearance, and suitability for the intended use.