Prototype Injection Molding

Accelerate prototyping with injection molding

Prototype injection molding is a fast, cost-effective solution for creating functional parts that closely mirror final production components. Ideal for testing, validation, and early user feedback, this process bridges the gap between concept and full-scale manufacturing.

Benefits of Prototype Injection Molding

Prototype injection molding offers faster turnaround than traditional tooling, helping you meet tight timelines and stay within rapid prototyping budgets. With production-grade materials and processes, your prototypes closely replicate final parts, providing accurate insight into real-world performance before full-scale manufacturing.

Or call (844) 237-2835

Prototype Injection Molding Considerations

Before beginning injection molding prototypes, we help customers clarify essential factors such as material selection, part design, and expected production volume to ensure optimal results.

-

Part Design

-

Material Selection

-

Mold Design

-

Manufacturing Capabilities

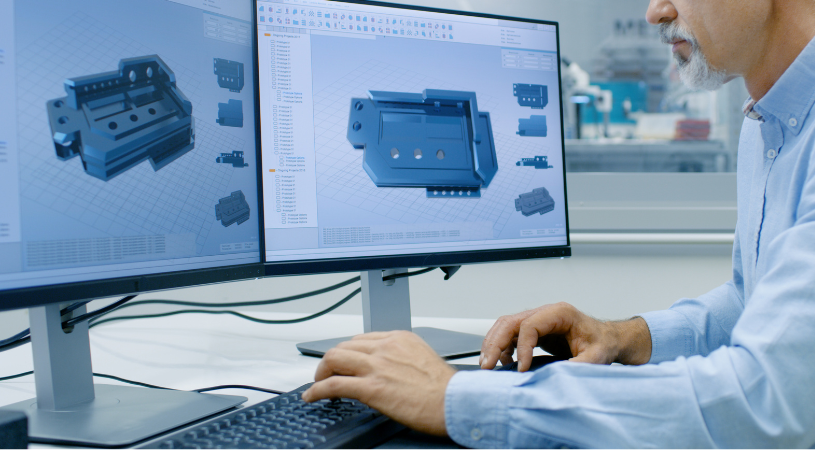

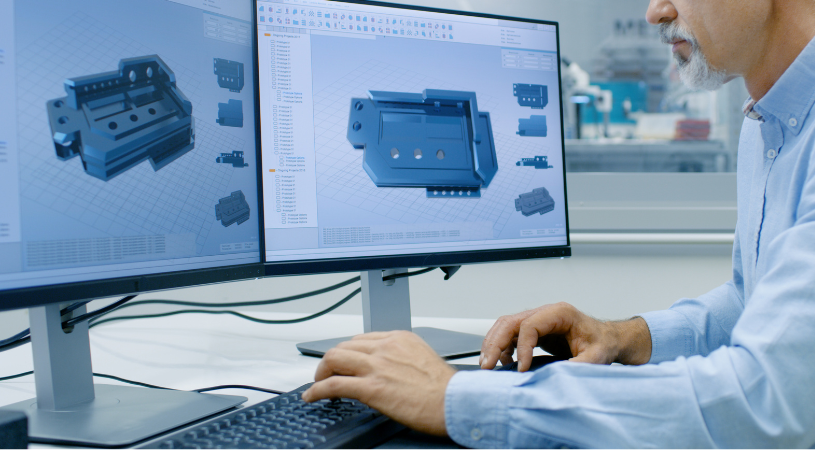

Part Design

Injection-molded prototype part design allows for assessing part fill and confirming geometry feasibility. It enables testing and verification of new dimensions and design modifications, ensuring quality before full-scale production.

Learn More

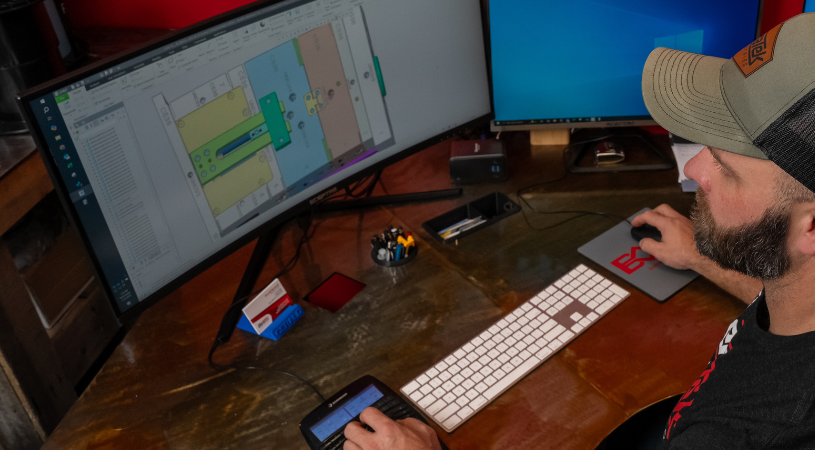

Material Selection

We offer efficient performance testing of various plastics, allowing you to assess and compare options without a significant financial investment. This ensures that you select the optimal material for your part’s performance and production requirements, while staying within budget.

Learn More

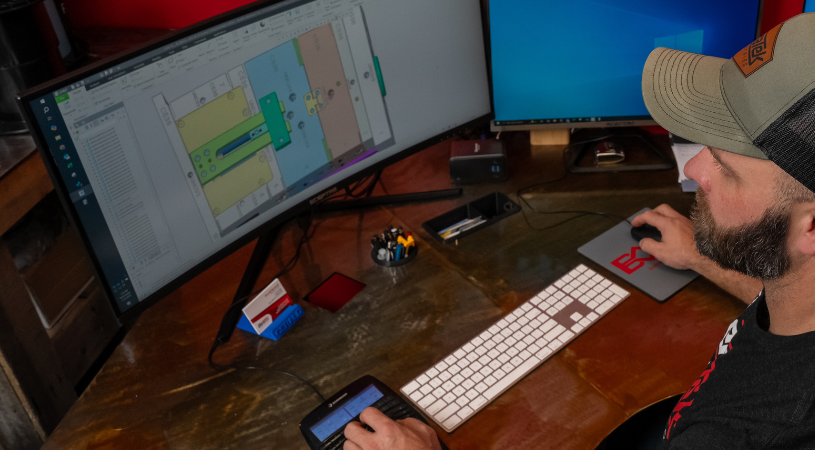

Mold Design

Once objectives and materials are determined, mold design becomes the focal point. Here, part geometry is transformed into mold components capable of accurately forming prototypes. Prototype mold design prioritizes speed and safety, ensuring the production of functional, production-equivalent parts that meet performance standards without delay.

Learn More

Manufacturing Capabilities

Identify the appropriate injection molding process—whether it’s two-shot molding, sandwich molding, or another method—based on part complexity and material requirements. We also assess production volume needs to ensure the process aligns with your timeline, cost-efficiency, and quality standards for optimal results.

Learn More

Part Design

Injection-molded prototype part design allows for assessing part fill and confirming geometry feasibility. It enables testing and verification of new dimensions and design modifications, ensuring quality before full-scale production.

Learn More

Material Selection

We offer efficient performance testing of various plastics, allowing you to assess and compare options without a significant financial investment. This ensures that you select the optimal material for your part’s performance and production requirements, while staying within budget.

Learn More

Mold Design

Once objectives and materials are determined, mold design becomes the focal point. Here, part geometry is transformed into mold components capable of accurately forming prototypes. Prototype mold design prioritizes speed and safety, ensuring the production of functional, production-equivalent parts that meet performance standards without delay.

Learn More

Manufacturing Capabilities

Identify the appropriate injection molding process—whether it’s two-shot molding, sandwich molding, or another method—based on part complexity and material requirements. We also assess production volume needs to ensure the process aligns with your timeline, cost-efficiency, and quality standards for optimal results.

Learn More

Prototype Testing

Testing injection molded prototypes is essential for identifying design flaws, ensuring functionality, and validating performance in the early stages of development.

Dimensional Accuracy

Dimensional accuracy in injection molding refers to how closely a molded part’s dimensions match the designed specifications. Achieving this requires careful consideration of factors like mold design, material properties, and process parameters.

Wall Thickness Consistency

Maintaining uniform wall thickness is crucial for achieving consistent quality and preventing defects like sink marks, warping, and voids. This consistence ensures proper material flow, cooling, and solidification throughout the part.

Strength Testing

Strength testing simulates real-world conditions to assess how the part withstands forces, identifying potential weaknesses early on. This allows for design improvements and ensures the part meets the required specifications before moving to mass production.

Visual Accuracy Meets User Validation

Ensuring every part not only looks precise but performs flawlessly in real-world use.

Visual Inspection

Subtle imperfections like minor shape deviations, poor surface finishes, part warpage, weld lines, and cosmetic flaws are often best detected through direct visual and tactile inspection. Human perception is highly sensitive to these details, making visual evaluation an essential step in identifying design or tooling issues early in the process.

Stakeholder Testing

Hands-on feedback from end users and stakeholders is invaluable. Real-world testing uncovers insights into ergonomics, functionality, and user experience that technical specifications alone may miss. Their input helps validate design decisions and uncover opportunities for improvement before final production.

Prototype Molding FAQs

What is prototype injection molding?

Prototype injection molding is a process used to create functional plastic parts using a mold, typically made from aluminum or soft steel, for low-volume testing and validation before full-scale production.

How is prototype injection molding different from production molding?

Prototype molds are typically made faster and from less durable materials, making them ideal for quick testing and iteration. Production molds are designed for high-volume use and long-term durability.

What are the requirements for injection molding?

Each injection mold design must have a gate, or an opening that allows the molten plastic to be injected into the cavity of the mold.

How many parts can I get from a prototype mold?

Prototype molds can usually produce anywhere from 100 to 10,000 parts, depending on the material, complexity, and mold material.

How long does it take to make a prototype mold?

Lead times vary, but most prototype molds can be completed in 1–4 weeks, offering a faster turnaround than production tooling.

Transition to Manufacturing

Prototype plastic injection molding is ideal for producing small batches of parts for testing, validation, and early-stage customer feedback. At BeraTek Industries, we make the process seamless, with no minimum order quantities, no red tape, and direct engineering support from day one. Whether you’re refining a concept or preparing for full-scale production, we’re equipped to deliver fast, functional prototypes that set the stage for manufacturing success.