Polyethylene injection molding

The Ultimate Guide to Versatility and Performance

Polyethylene (PE) stands as the world’s most widely used plastic, admired for its simplicity and adaptability. This thermoplastic polymer comes in various densities and formulations, each offering unique properties to meet diverse application requirements. From lightweight films to durable industrial parts, PE’s versatility makes it a cornerstone material in packaging, construction, consumer goods, and beyond.

Common Brand Names

These brands are recognized for their high-quality polyamide materials, providing reliable performance across a range of demanding applications.

- Dowlex®

- Marlex®

- ExxonMobil™ HDPE

- LyondellBasell Alathon®

Moldability Characteristics

Easy Processing

PE can be easily processed through various methods, including injection molding, blow molding, and extrusion, making it suitable for a wide range of product forms.

Versatile Design

Its flexibility allows for the production of everything from thin films to rigid containers, accommodating complex shapes and sizes.

Excellent Environmental Stress Crack Resistance

Especially in HDPE, which is crucial for products exposed to harsh conditions.

Mechanical Properties

Durability

PE offers excellent impact resistance and toughness, with HDPE being particularly robust for high-strength applications.

Chemical Resistance

Resists acids, alkalis, and most solvents, making it suitable for chemical containers and pipelines.

Flexibility

LDPE and LLDPE are known for their flexibility and are used in applications requiring pliable material, such as squeeze bottles and tubing.

-

Packaging

-

Construction

-

Consumer Goods

-

Agricultural Applications

Packaging

From flexible wrappers and shopping bags (LDPE, LLDPE) to rigid containers and milk jugs (HDPE).

Learn More

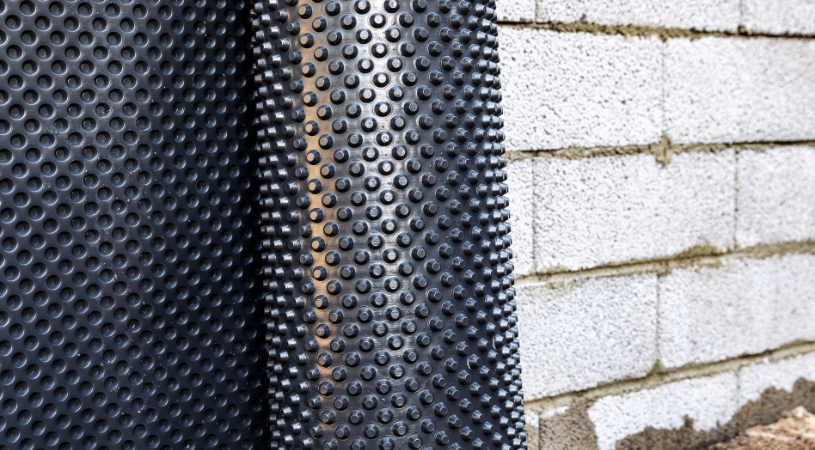

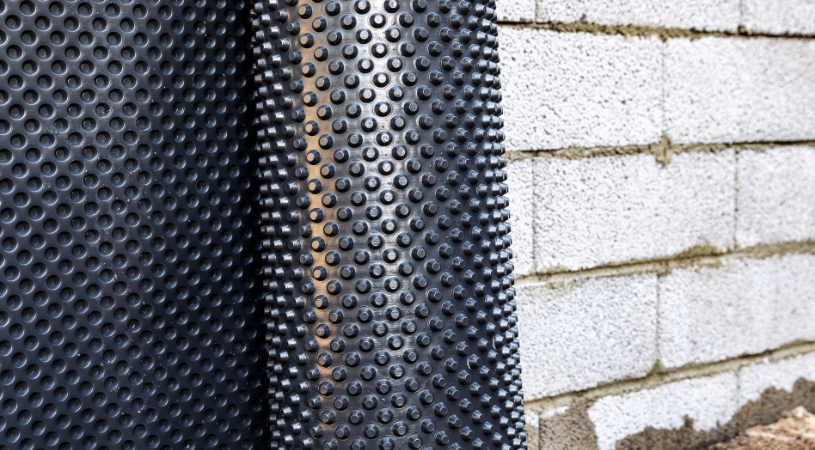

Construction

Pipe systems, geomembranes, and insulation materials benefit from PE’s durability and resistance properties.

Learn More

Consumer Goods

Toys, housewares, and sporting goods utilize PE for its safety, durability, and ease of maintenance.

Learn More

Agricultural Applications

Watering systems and silage films take advantage of PE’s environmental resistance and flexibility.

Learn More

Packaging

From flexible wrappers and shopping bags (LDPE, LLDPE) to rigid containers and milk jugs (HDPE).

Learn More

Construction

Pipe systems, geomembranes, and insulation materials benefit from PE’s durability and resistance properties.

Learn More

Consumer Goods

Toys, housewares, and sporting goods utilize PE for its safety, durability, and ease of maintenance.

Learn More

Agricultural Applications

Watering systems and silage films take advantage of PE’s environmental resistance and flexibility.

Learn More