Nylon Injection Molding

Engineering Strength and Flexibility

Polyamide (Nylon) is a synthetic polymer famed for its exceptional mechanical strength, thermal stability, and resistance to wear and chemicals. It is widely used in engineering and high-performance applications, offering a unique combination of toughness, flexibility, and thermal resistance. Nylons are available in various grades, including Nylon 6, Nylon 66, and more specialized types, each tailored to specific application needs.

Common Brand Names

These brands are recognized for their high-quality polyamide materials, providing reliable performance across a range of demanding applications.

- Zytel® by DuPont

- Technyl® by Solvay

- Ultramid® by BASF

- Akulon® by DSM

Nylon Moldability Characteristics

Ease of Processing

Nylon can be processed using various methods, including injection molding, extrusion, and blow molding, allowing for versatile part design.

Moisture Absorption

Nylon’s moisture absorption can affect its properties and dimensions; thus, conditioning and proper design considerations are essential.

Finish and Color

Nylon components can achieve excellent surface finishes and can be easily colored, enhancing aesthetic qualities without sacrificing performance.

Mechanical Properties

High Strength and Toughness

Nylons are known for their high tensile strength and impact resistance, making them suitable for load-bearing applications.

Thermal Resistance

With a high melting point, Nylon maintains its properties across a broad temperature range, suitable for under-the-hood automotive parts and high-temperature environments.

Wear and Chemical Resistance

Excellent resistance to abrasion and many chemicals, ideal for gears, bearings, and under-hood automotive components.

-

Automotive Components

-

Electrical and Electronics

-

Consumer Goods

-

Industrial Machinery

Automotive Components

Engine covers, door handles, and other parts benefit from Nylon’s durability and thermal stability.

Learn More

Electrical and Electronics

Connectors, cable ties, and component housings utilize Nylon’s insulating properties and strength.

Learn More

Consumer Goods

High-strength sports equipment, durable kitchenware, and lightweight fashion items showcase Nylon’s versatility.

Learn More

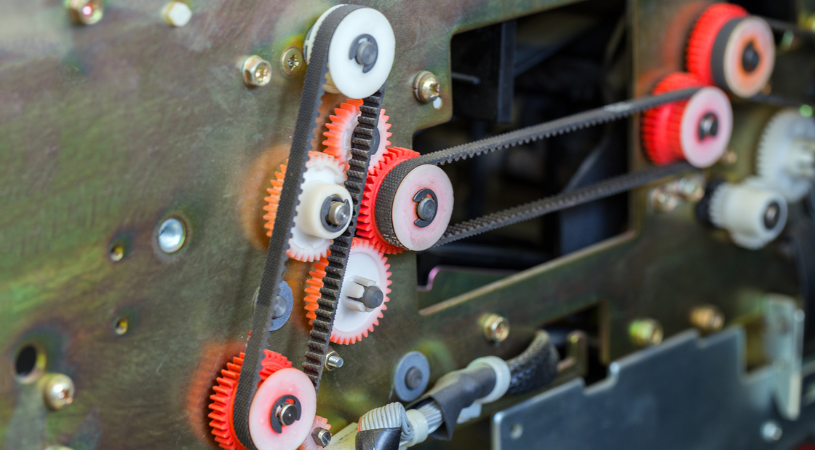

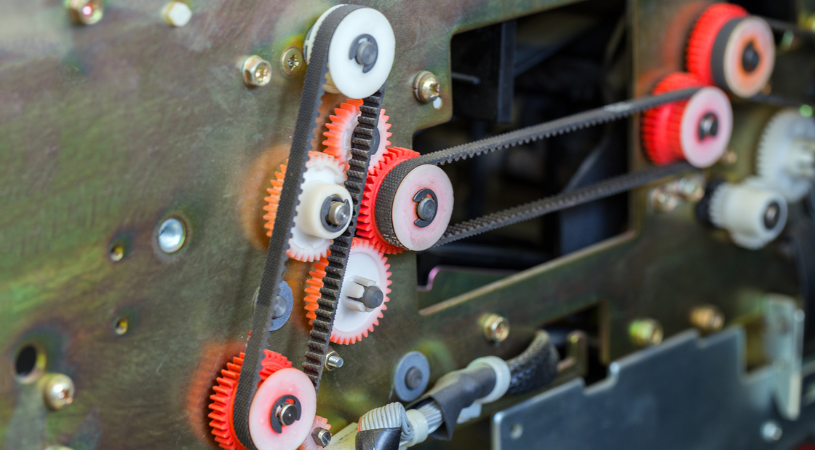

Industrial Machinery

Gears, rollers, and bearings rely on Nylon’s wear resistance and mechanical strength for smooth operation.

Learn More

Automotive Components

Engine covers, door handles, and other parts benefit from Nylon’s durability and thermal stability.

Learn More

Electrical and Electronics

Connectors, cable ties, and component housings utilize Nylon’s insulating properties and strength.

Learn More

Consumer Goods

High-strength sports equipment, durable kitchenware, and lightweight fashion items showcase Nylon’s versatility.

Learn More

Industrial Machinery

Gears, rollers, and bearings rely on Nylon’s wear resistance and mechanical strength for smooth operation.

Learn More