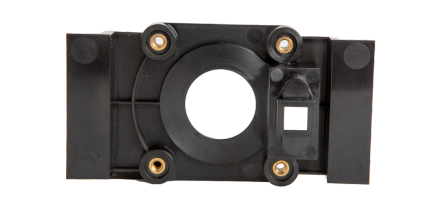

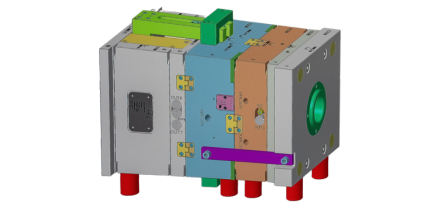

mold design

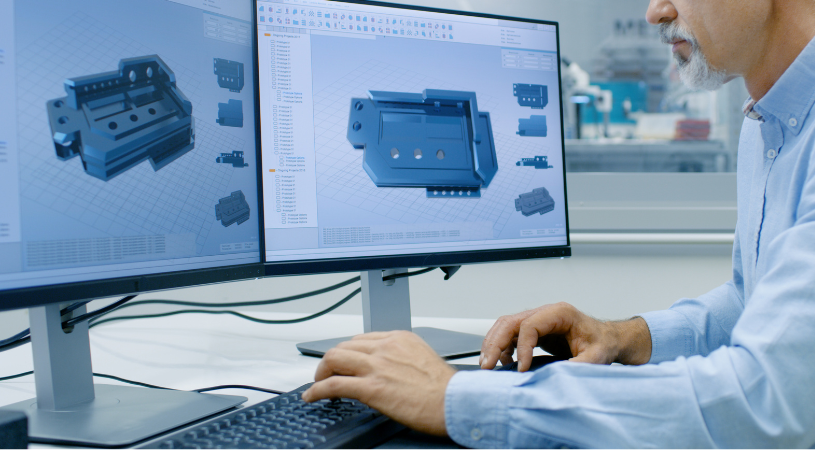

product design & engineering

Our engineering and product design team works with you to select the best materials for your production, simplify assembly operations, and improve design features for efficient production. We’ll immerse you in the process, from 3D CAD modeling and prototyping to mold design, ensuring complete transparency, precision, and a seamless development process.

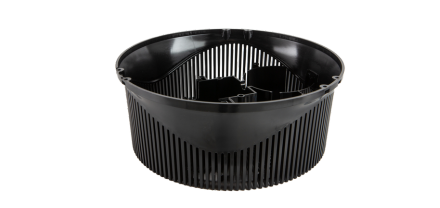

Our Work

We thrive on tackling complex challenges and delivering exceptional results.

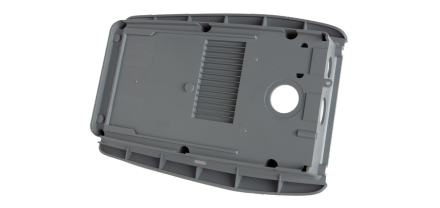

Every project is an opportunity to push the boundaries of innovation, applying our injection molding design expertise to create smarter, more efficient solutions. Whether refining an existing product or developing something entirely new, we approach each challenge with a problem-solving mindset, ensuring your vision is brought to life with precision and excellence.

Expertise

Product Design and Engineering Services

A strong injection mold design is essential before manufacturing plastic parts. Our team brings a diverse range of technical expertise, allowing us to provide strategic recommendations that enhance the usability, functionality, and overall performance of your products.

Mechanical Engineering Expertise

With extensive expertise in plastic part development, our mechanical engineers apply advanced engineering principles and technologies. This ensures that our solutions achieve peak performance, durability, and cost-effectiveness for various applications.

Metal to Plastic Conversion

Transitioning from metal components to plastic can offer numerous benefits, including weight reduction, cost savings, and improved manufacturing efficiency. Our team specializes in evaluating metal parts and redesigning them for plastic injection molding without compromising performance.

Custom Injection Molding Design Guidelines

Bosses

Bosses should be designed at a depth of 30% the wall thickness and with a 30% edge groove. Attach them to side walls or ribs for structural integrity.

Quality

Elevating Product Design for Optimal Performance

Exceptional injection molded product design is not just innovation and aesthetics, but the ability to optimize designs for efficient manufacturing processes.

Whether it’s selecting the right materials, simplifying the assembly process, or fine-tuning the design for manufacturing scalability, we’re committed to creating injection-molded products that are not only innovative but production-ready.

Process

Concept to Completion

Step 1

Concept Development & Research

We begin with brainstorming ideas, defining product requirements, and conducting market and feasibility research. Our designers and engineers collaborate to outline functionality, user needs, and material considerations.

Step 2

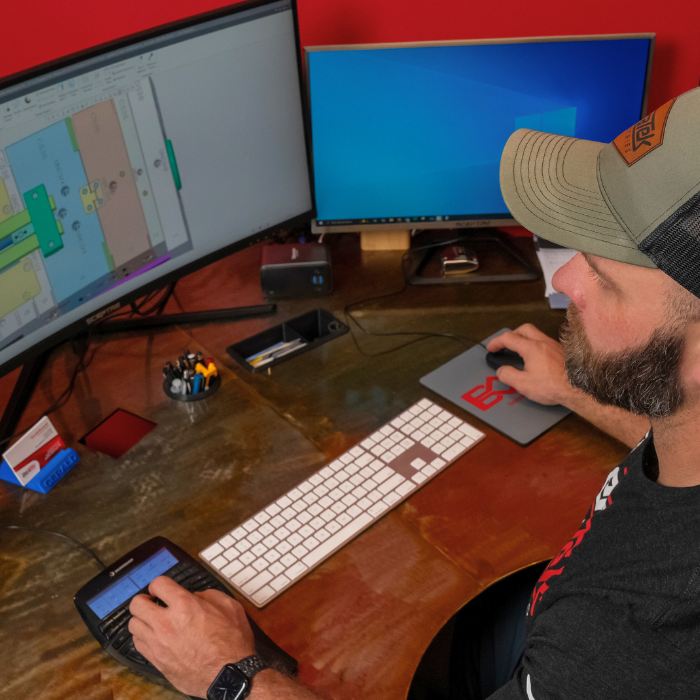

Detailed Design & Engineering

Using CAD software, the product takes shape with precise dimensions, material selection, and manufacturability considerations. Design for Manufacturing (DFM) principles are applied to ensure efficiency and cost-effectiveness in production.

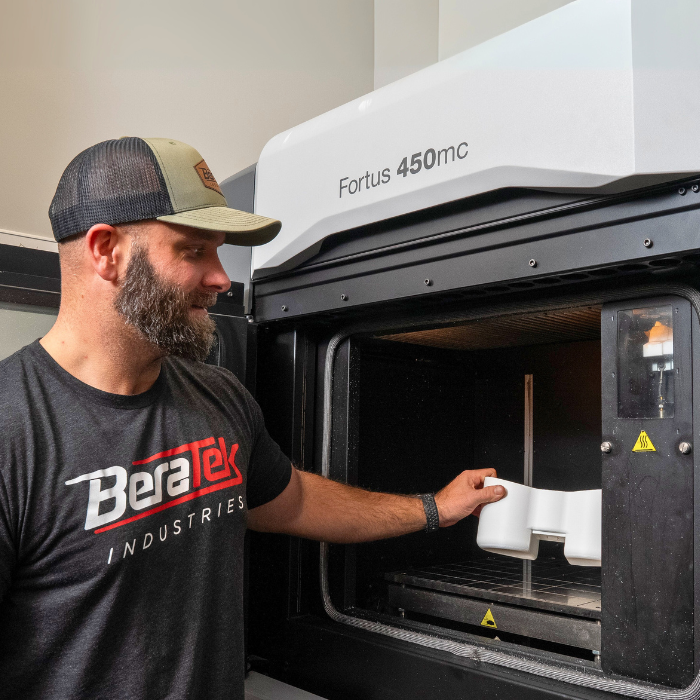

Step 3

Prototyping & Validation

A prototype is created using 3D printing, CNC machining, or other rapid prototyping methods. The prototype undergoes functional testing, user evaluation, and refinement to validate the design before moving toward full-scale production.

Industries We Serve

See how major industries use plastic injection molding to produce repeatable products of any size, shape, or thermoplastic material.

Product Design & Engineering FAQs

What engineering specialties do you bring to the table?

- Mechanical Engineering Expertise: We apply advanced principles to create plastic parts that balance performance, durability, and cost-effectiveness.

- Design for Manufacturability (DFM): We optimize designs early to streamline manufacturing, lower costs, and accelerate your time-to-market.

- 3D CAD Modeling: We build detailed digital models—running simulations for stress, thermal, and other performance factors—to validate designs before production.

- Reverse Engineering: We deconstruct existing products to refine design and functionality, ensuring improved and market-ready versions.

- Metal-to-Plastic Conversion: We redesign metal components for plastic injection molding to reduce weight, save cost, and simplify manufacturing without sacrificing quality.

How does BeraTek approach the design process from concept through production?

Our process unfolds in three phases:

- Concept Development & Research: We define your product’s requirements and blend market insights to craft a tailored concept.

- Detailed Design & Engineering: Leveraging CAD tools and DFM principles, we refine the design for cost-efficiency and manufacturability.

- Prototyping & Validation: We produce physical prototypes using methods like 3D printing or CNC machining. These are tested and refined until ready for production.

Why is strong injection mold design important?

A well-designed mold is essential for precision, performance, and successful manufacturing of plastic parts. Our strategic approach enhances usability, functionality, and overall product quality.

What practical design guidelines do you follow for injection molding?

To ensure efficient and high-quality production, we recommend:

- Undercuts: Minimize complexity and cost by using coring instead of undercuts.

- Wall Thickness: Maintain even wall thickness to avoid sink marks and voids, reduce cycle times, and prevent defects.

- Draft Angles: Use 0.5°–5° draft on textured surfaces to aid part release from the mold.

- Ribs/Gussets: Keep ribs 40–60% the thickness of outer walls and include draft for molding ease.

- Bosses: Make bosses 30% of the wall thickness, add a 30% edge groove, and attach them to side walls or ribs for stability.

Why should I choose BeraTek for Product Design & Engineering?

Our vertically integrated, in-house team ensures seamless progression from design through production. With a deep expertise in injection molding and a commitment to quality at every stage, you’ll experience efficient, transparent, and scalable engineering support—built to get your product from concept to market success.