Design Best Practices for Flawless Injection Molded Components

At BeraTek Industries, we know that even the smallest design choice can determine whether your injection molded part performs flawlessly—or fails in the field. Injection molding is one of the most cost-effective, scalable manufacturing methods available, but only if your design is optimized for the process.

In this guide, we’ll walk through the essential best practices every engineer, designer, or product developer should follow to ensure strong, consistent, and production-ready molded components.

Download this article as an infographic!

1. Choose the Right Material from the Start

Your material isn’t just the “stuff” your part is made of—it dictates strength, flexibility, durability, and aesthetics.

Popular material choices include:

- Polypropylene → lightweight, chemical-resistant, cost-effective

- ABS → rigid, strong, easy to process

- Nylon → impact-resistant, excellent for wear-and-tear applications

👉 Pro Tip: Each resin shrinks differently during cooling. If shrinkage is ignored at the design stage, your part dimensions won’t match the finished mold.

2. Maintain Uniform Wall Thickness

Consistent wall thickness = consistent quality. Uneven thickness can lead to warping, sink marks, or voids in your parts.

Guideline:

- Target 2–4 mm for most materials.

- Use ribs, gussets, or bosses to add strength without bulky walls.

👉 Remember: Thin walls cool faster, reducing cycle time and improving efficiency.

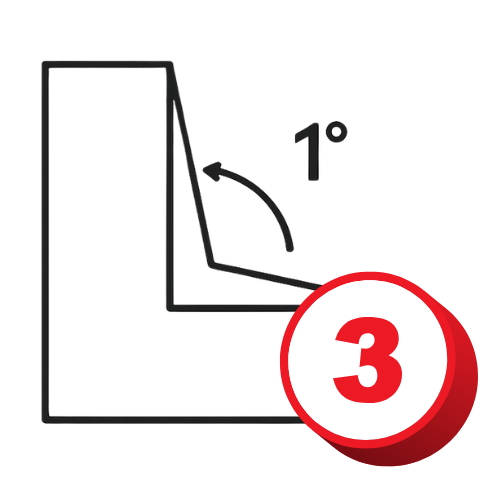

3. Add the Right Draft Angles

Draft angles are essential for smooth part ejection from the mold. Without them, parts stick, surfaces scuff, and cycle times increase.

Recommended drafts:

- Smooth surfaces: at least 1° per side

- Textured surfaces: 3° or more

👉 The more textured the finish, the more draft you’ll need.

4. Eliminate Stress Concentrations

Sharp corners and abrupt changes in geometry can create weak points. Instead, use fillets and radii to spread stress evenly.

Design Tips:

- Add fillets (0.5–1 mm radius minimum) at inside corners.

- Use ribs to strengthen flat areas.

- Support bosses properly to prevent cracking.

5. Plan Ahead for Gates & Parting Lines

Gate location affects how resin flows into the mold, which impacts both performance and appearance.

Best practices:

- Place gates in non-visible areas.

- Collaborate early with your mold maker to reduce weld lines.

- Consider parting line location to minimize flash and cosmetic concerns.

👉 Smart gating ensures fewer cosmetic defects and stronger parts.

6. Validate with Simulation & Prototyping

Don’t wait until production to discover flaws. Testing early saves time and money.

Tools to use:

- Moldflow analysis → simulates resin flow to predict warping, short shots, or weld lines.

- 3D printed prototypes → validate geometry and fit before investing in tooling.

“Designing with manufacturability in mind is the fastest way to reduce costs and accelerate your product launch.”

— BeraTek Industries Engineering Team

Why Work with BeraTek?

At BeraTek, we don’t just manufacture injection molded parts—we partner with you to design smarter from the start. Our engineers bring hands-on experience in both design and production, ensuring your components are built for durability, efficiency, and cost savings.

Whether you’re developing a consumer product, a medical device, or an industrial component, our team is here to help you:

- Select the best material

- Optimize your design for manufacturability

- Deliver flawless, production-ready parts every time

Ready to Get Started?

Don’t risk costly redesigns and delays. Partner with BeraTek to design and manufacture components that meet your exact needs.