7 Steps to Turn Your Idea into a Product and Start Selling Online

Having a product idea is exciting. Turning that idea into something people can actually buy is where most founders get stuck.

Design questions, prototyping costs, manufacturing risks, and marketing decisions can quickly turn a good idea into a stalled project. The reality is that successful products are rarely accidents. They are built through a structured, repeatable process that reduces risk at every stage.

Below is our 7-step product development and launch framework we use to take ideas from concept to real-world sales. Whether you are an inventor, entrepreneur, or business owner, this process helps you move forward with confidence instead of guesswork.

Download this article as an infographic!

Step 1: Product Design (Design for Manufacturing First)

Every successful product starts with intentional design.

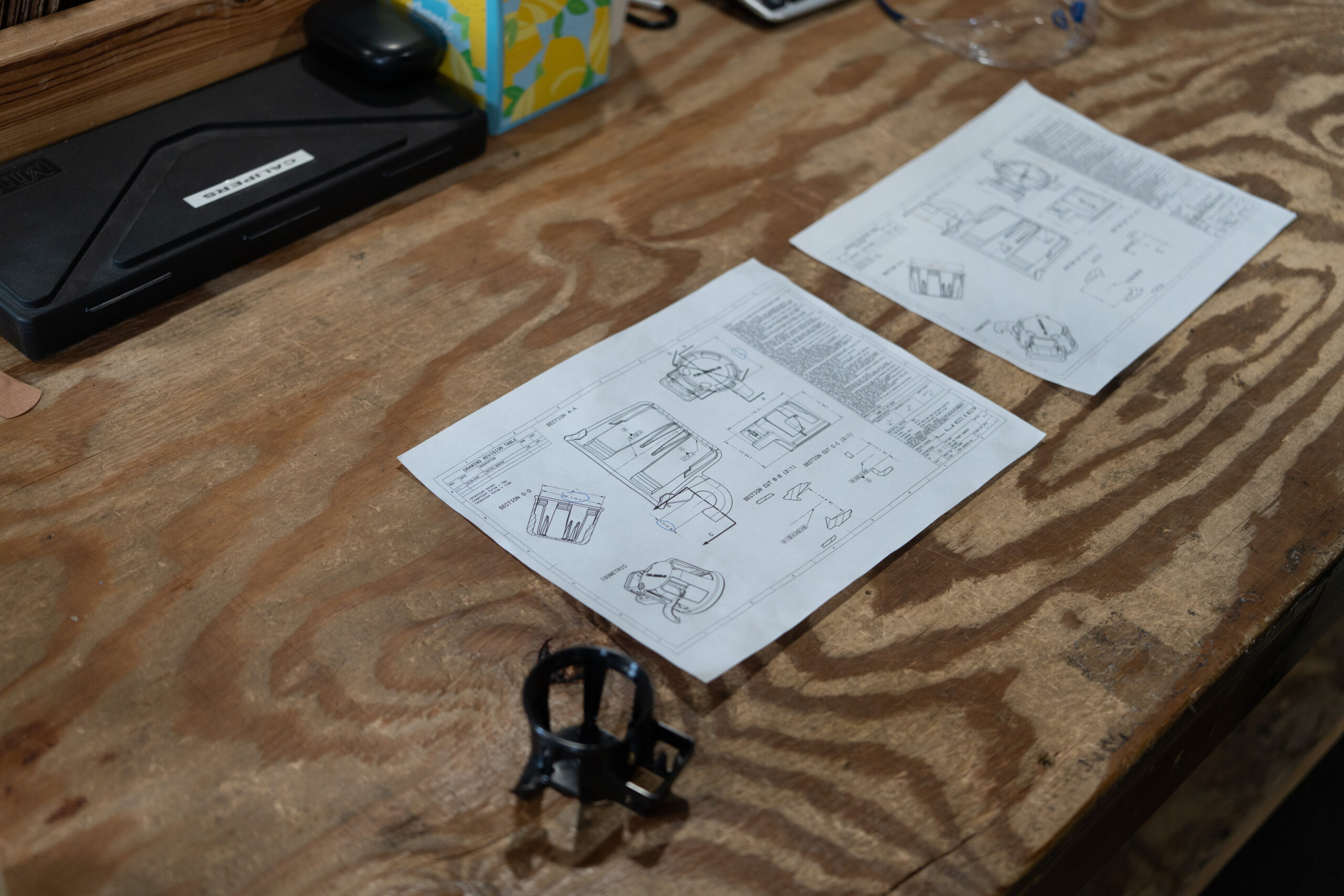

Before you think about prototypes or manufacturing, your idea needs to be translated into a 3D CAD design. This is not just about making something that looks good. It is about making something that can be manufactured efficiently, consistently, and affordably.

Designing for manufacturing from the beginning helps you:

- Avoid expensive redesigns later

- Reduce tooling and production costs

- Shorten your time to market

- Communicate clearly with manufacturers

An experienced product designer or engineer will consider material selection, wall thickness, draft angles, tolerances, and assembly requirements during the design phase.

Key takeaway:

A product that is designed well on day one will save you months of rework and thousands of dollars down the line.

Step 2: Prototyping (Turn the Idea Into Something Real)

Once the CAD design is complete, the next step is prototyping.

Prototypes allow you to move from theory to reality. They help answer one critical question: Does this product actually work in the real world?

For many products, 3D printing is the fastest and most cost-effective way to create an initial prototype. However, depending on your product, you may also consider:

- CNC machined prototypes for higher strength or precision

- Urethane casting for small production-like runs

- Hybrid or hand-built prototypes for early proof of concept

Each method has tradeoffs in cost, speed, and realism. The goal is not perfection. The goal is to create something tangible that can be evaluated, tested, and improved.

Step 3: Testing (Form, Fit, and Function)

Testing is where assumptions are challenged and problems are exposed.

Your prototype should be evaluated for:

- Form: Does it look and feel right?

- Fit: Do all parts assemble correctly and consistently?

- Function: Does it solve the problem it was designed to solve?

This stage often reveals issues that were not obvious in CAD. That is normal and expected. Discovering problems now is far better than discovering them after production tooling has been created.

Effective testing helps you:

- Identify weak points or failure risks

- Improve usability and ergonomics

- Confirm performance expectations

The more honest and thorough your testing, the stronger your final product will be.

Step 4: Iteration (Refine With Purpose)

Iteration is the process of improving your product based on what testing reveals.

Most products go through multiple design-test cycles before they are ready for customers. Each iteration should be intentional and data-driven, not random.

Best practices for iteration include:

- Updating the CAD design after each testing round

- Making controlled changes so results are measurable

- Avoiding unnecessary feature creep

- Keeping manufacturing constraints in mind

Expert Tip:

The goal is not perfection. The goal is reaching a minimum viable product (MVP) that performs reliably and solves a real problem. Spending too long iterating can delay validation and drain resources. Knowing when to move forward is just as important as knowing what to improve.

Step 5: Customer Validation (Prove There Is Demand)

Customer validation is one of the most critical steps and one of the most commonly skipped. Before committing to full-scale manufacturing, you need evidence that people actually want your product and are willing to use or buy it.

There are two primary validation paths:

If your prototype functions like a production product:

- Share samples with potential customers

- Collect feedback on usability, value, and effectiveness

- Observe how people interact with the product without instruction

If your prototype is not production-ready:

- Use photos, videos, or demonstrations

- Clearly communicate the problem and solution

- Gather feedback on perceived value and interest

Validation reduces risk and helps ensure you are not building a product based solely on internal assumptions.

“Most product ideas don’t fail because they’re bad ideas. They fail because they weren’t designed with real-world manufacturing in mind from the start. When you think through how something will actually be made, everything else gets easier.”

— BeraTek Industries Engineering Team

Step 6: Manufacturing (From Prototype to Production)

Once customer validation is strong, it is time to move into manufacturing.

This step requires alignment between your product design and the manufacturing method chosen earlier. Common manufacturing options include:

- Plastic injection molding

- CNC machining

- Sheet metal fabrication

- Assembly-based manufacturing

Plastic injection molding is often one of the most cost-effective options for high-volume production, but it is not always the right choice for every product.

At this stage, you should:

- Finalize materials and finishes

- Lock down tolerances and specifications

- Select and vet manufacturing partners

- Prepare for tooling and production setup

A smooth manufacturing phase depends heavily on the quality of your earlier design and validation work.

Step 7: Marketing and Sales (Launch and Scale)

Manufacturing is not the finish line. Selling is.

Once your product is ready, you need a clear strategy for how customers will find and purchase it. For many startups and entrepreneurs, ecommerce is the fastest and most scalable path to market.

Common ecommerce channels include:

- Your own direct-to-consumer website

- Amazon

- eBay

- Etsy

- Other niche marketplaces

Launching online allows you to test pricing, messaging, and demand quickly while gathering valuable customer feedback.

Pro Tip: Long-term success depends on trust. Clear communication, fast support, and great customer service drive reviews, referrals, and repeat purchases.

Proven Results Using This Process

At BeraTek, this 7-step framework is not theoretical. It is built on real execution.

Using this process, we have:

- Developed multiple physical products from concept to market

- Manufactured at scale using proven partners

- Generated over $2,000,000 in ecommerce sales in the last three years

Products developed through this process include:

- VuSee

- Power Perch

- Hold & Go Slow Cooker

Each product followed the same disciplined approach, reducing risk while increasing speed to market.

Ready to Get Started?

If you have an idea and are serious about bringing it to market, the right process makes all the difference.

We help entrepreneurs and businesses:

- Launch and sell successfully online

- Design for manufacturing

- Prototype efficiently

- Validate real customer demand

- Manufacture with confidence

👉 Request a Consultation today and bring your concept to life with confidence.