Why Prototype?

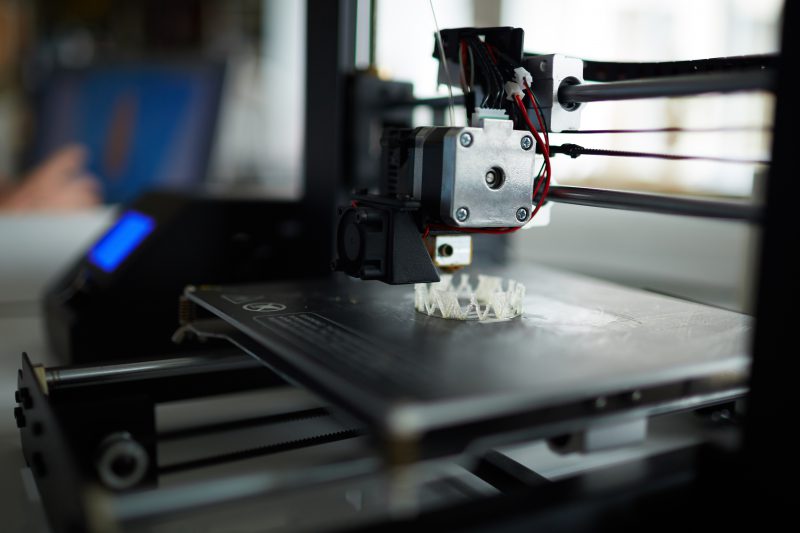

It’s no secret, the most important piece of the product development cycle is a buttoned-up CAD model designed for manufacturing. However, prototyping plays a vital role in arriving at the manufacturable design. Product design is truly an R&D process. You design something you think will work, test it, iterate and repeat. With the rise of 3D printing and an increase in prototyping options available on the market, we can hold a sample of our final product quicker than ever. Now that we have a prototype in hand we can do the necessary customer discovery to ensure our design serves the need of the target market. It’s amazing to see a design progress from prototype 1 to prototype X. We often discount just how much the little things matter in product development. Furthermore, our personal opinions typically have little weight. You won’t know if you have something special until you share it with your target market in physical form and gather feedback!

What if my prototype isn’t a true representation of the final product?

While prototyping has come a long way over the past decade, there are still circumstances in which your prototype won’t quite mimic the look, feel, and/or function of the final product. In many cases, 3D printing is sufficient for yielding a nearly production quality prototype that is often functional as well. However, depending on the functionality requirements of the product, you may have to consider alternative prototyping options to get that warm fuzzy before diving head first into manufacturing. One that I often leverage is urethane casting. Urethane casting is the process of making a crude mold often in the $1-2K price range that will allow for the production of 10-25 quality prototypes. The urethane material family is rather diverse and likely has a product close to the final product material specification. Urethane casting goes a step beyond 3D printing and makes up some of the slack when proving out the function of a product. However, casting isn’t always the answer either. If the functional requirements stem beyond the abilities of casting, I’d suggest considering a machined prototype and/or prototype injection molding.

I have that warm fuzzy feeling, what next?

Now that you’ve done your due diligence through prototyping, you’ve gathered customer feedback, revised the design relative to the common feedback points and settled on a product that delivers on the needs of the target market, it’s time to move onto manufacturing. Often times the golden ticket required to jump over the line into manufacturing is a design for manufacturing (DFM) analysis. This is the time when an experienced manufacturing engineering evaluates your design to ensure it’s optimized for manufacturing and makes any recommendations on design changes to improve manufacturability and/or reduce your tooling investment. You’ll often find that there are several ways to manufacture a product, but what is important is evaluating the best bang for your buck. If a slight change to the angle of a side wall removes the need for slides in the mold, you’ll see a nice reduction in tooling cost. DFM is the time when you can start seeing some $$$$ move back into your pocket through design changes. Cha-Ching!