Product Prototyping

Rapid Prototyping for Injection Molding Success

Speed and precision are critical in the prototyping phase, and we exceed in both. Our rapid prototyping services allow you to test and upgrade your concepts quickly, reducing time to market. We use the latest materials and techniques to produce prototypes that closely match the final product, enabling you to make informed decisions early in the development process.

about us

We perfect product designs with ingenuity and an iterative prototyping process.

Bridging the gap between initial design and mass production, we integrate feedback throughout the prototyping process to refine and validate products for their intended applications.

services

Product Prototyping Services

We use additive manufacturing to enable faster iterations and refinements while identifying design flaws early. Our range of manufacturing processes allows us to produce high-quality industrial prototypes efficiently. Consult our engineering team to determine the best process and material for your product.

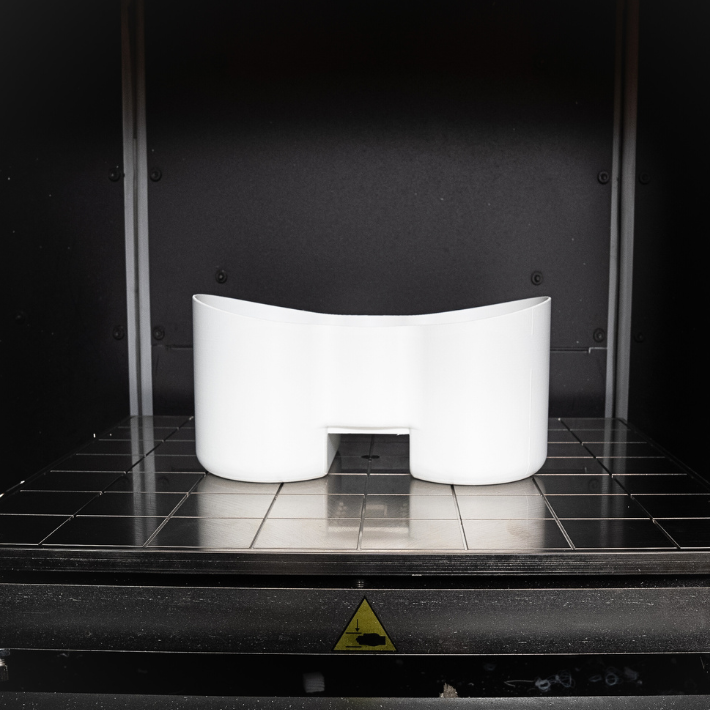

3D Printing

Explore the future of manufacturing with our cutting-edge 3D printing services. Perfect for intricate geometries and rapid prototyping, our 3D printing technology offers quick turnaround times and exceptional design flexibility.

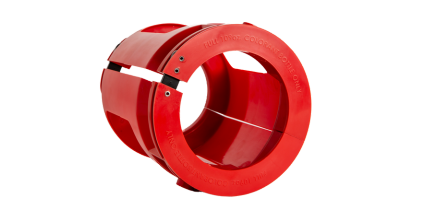

CNC Machining

CNC machining services offer high accuracy and versatility, producing prototypes from a wide range of materials – metal or plastic with exact specifications. This approach is ideal for functional prototypes that challenge mechanical strength and continuity.

Urethane Casting

Perfect for low-volume production and prototypes that mimic molded parts, our urethane casting process offers a cost-effective solution without compromising on quality. Get parts that are durable, flexible, and aesthetically pleasing.

Prototype Injection Molding

Bridge the gap between prototyping and mass production with our prototype injection molding services. Ideal for testing material properties and design for manufacturability, this method delivers high-quality parts efficiently.

Advantages of Plastic 3D Printing

Precision

We use the latest generation of 3D printing technologies to meet demanding tolerances.

Scalability

Whether it is one, or thousands, BeraTek has the 3D printing capacity to meet your needs and lead time

Durability

With engineered materials like nylon, polycarbonate, or even ULTEM, 3D printed plastic parts are tough and functional.

Rapid Turnaround

Get high-quality plastic parts delivered fast with our rapid prototyping process — ready in just a few days.

Complex Geometries

3D printing can create complex parts without increased costs.

Low Cost

3D printing is inexpensive and has no minimum order quantities.

3D Printing vs CNC Machining

CNC machining uses subtractive processes, where material is removed from the feedstock to achieve its final form. This involves drilling holes, boring slots and pathways, and shaping material stock into new forms with diverse tapers, diameters, and configurations.

For subtractive manufacturing, shapes are achieved by the subtraction of material. This contrasts with other types, such as additive manufacturing, where materials are added, layered, and deformed to a specified shape. It also contrasts with injection moldin,g where the material is injected in a different state of matter, using a mold, and formed to a specified shape.

CNC machining is versatile and can be used with various materials, including metals, plastics, wood, glass, foam, and other composite materials. This versatility has helped make CNC machining a popular choice across industries, enabling designers and engineers to fabricate products efficiently and precisely.

Quality

Accelerating Time-to-Market & Faster Product Development

We offer flexible prototyping methods, including 3D printing and CNC machining, tailored to the scope and complexity of your project. Our ability to scale the process ensures we meet client requirements and timelines effectively.

With efficient parallel production of multiple prototypes, we can accommodate tight deadlines or large batch requests. Rapid prototyping techniques allow for quick adjustments and refinements based on feedback, ensuring your product evolves seamlessly.

Process

Concept to Completion

Step 1

Concept to Prototype Design

Before creating a prototype, the design is finalized using CAD modeling and engineering analysis. This step ensures that the prototype accurately represents the final product’s dimensions, materials, and functionality.

Step 2

Prototype Fabrication

Using advanced manufacturing techniques like 3D printing, CNC machining, or injection molding, a physical prototype is produced. Material selection and fabrication methods are tailored to match real-world performance needs.

Step 3

Testing & Refinement

The prototype undergoes rigorous testing for fit, function, and durability. Our engineers analyze the results, make necessary refinements, and iterate the design if needed—ensuring a flawless transition to full-scale production.

Choosing Materials for Prototyping

Many injection molding materials offered at BeraTek Industries are available for prototype applications. Depending on your product, our experienced team can guide your decision in which material would be best for you to perform functional testing prior to production.